AAE Prof. Alexey Shashurin's invention may revolutionize sterilization

New technology being developed by AAE at Purdue may one day impact your experiences buying fresh produce and being treated at a medical office.

The technology

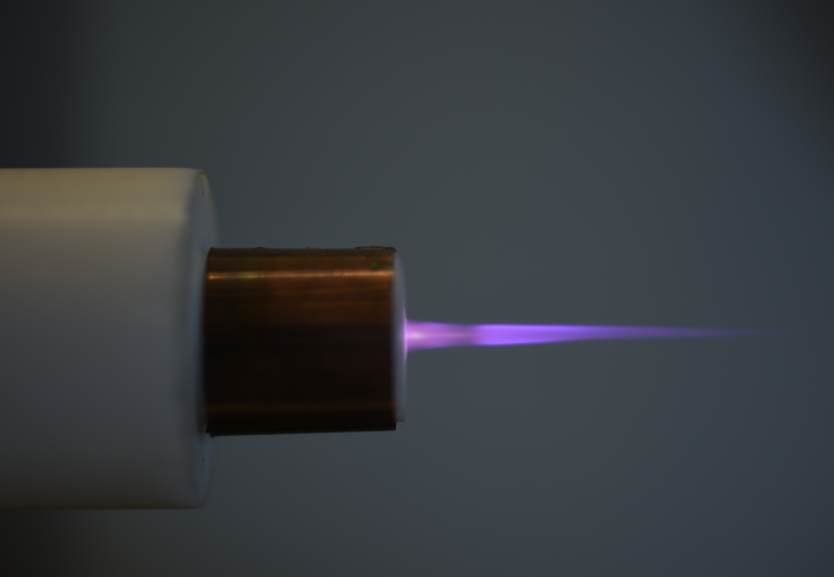

AAE Prof. Alexey Shashurin and PhD student Xingxing Wang invented DC voltage driven cold plasma technology that has the potential to revolutionize the cost and efficacy of sterilization in a wide spectrum of applications, ranging from foods to medical tools. Initial studies of the novel technology were published in two research papers and led to the filing of a provisional patent application.

The invention also won an award from Innovation Corps (I-Corps), a program funded by the National Science Foundation. Now, the inventors have formed a “Cold Plasma Sterilization Team,” with support from Dr. D.H.R. Sarma in Purdue’s Office of Technology Commercialization.

“We are currently working with industrial companies to identify the most promising paths for commercialization of the invented technology,” Shashurin says. “We are also constructing an adaptable prototype of the cold plasma system to demonstrate the effectiveness of the proposed sterilization approach to potential customers.”

Recent work has demonstrated that cold plasmas can be generated in self-oscillatory regime, when sequence of streamer-type breakdowns in gas flow is driven by purely DC high voltage. This approach differs from the traditional AC and pulsed-DC, where breakdown repetition rate is governed by the frequency of discharge driving voltage. The repetition frequency of the breakdowns in this innovative approach can be controlled by the geometry of discharge electrodes and surroundings.

DC voltage driven cold plasma technology has tremendous fundamental advantages over the traditional AC and pulsed-DC systems, including very effective mitigation of unwanted breakdowns and corona, elimination of electromagnetic interference, significant improvement of breakdown and electric shock safety, and overall simplicity of the system and enables multiple commercial applications.

The change

Sometimes ideas do not work out the way we think they might. That’s one of the lessons the “Cold Plasma Sterilization Team” has learned along the way.

The team’s initial thought was to use the invention for sterilization for pharmaceuticals. They found out, after interviews with industry experts, that the cold plasma technology is not appropriate for this segment. While plasma kills the bacteria, it does not remove it from the final product. Thus, it’s not an acceptable method for pharmaceuticals.

Instead, the team is focused on the sterilization of medical instruments and in food processing, along with on-site sterilization for fresh produce in grocery stores.

“We think we have found a good customer segment, which is a different group than the one we thought initially,” Wang says.

A utility patent application has been filed by Purdue’s Office of Technology Commercialization and is available for licensing. For those interested in learning more about licensing opportunities, please email OTCIP@prf.org.