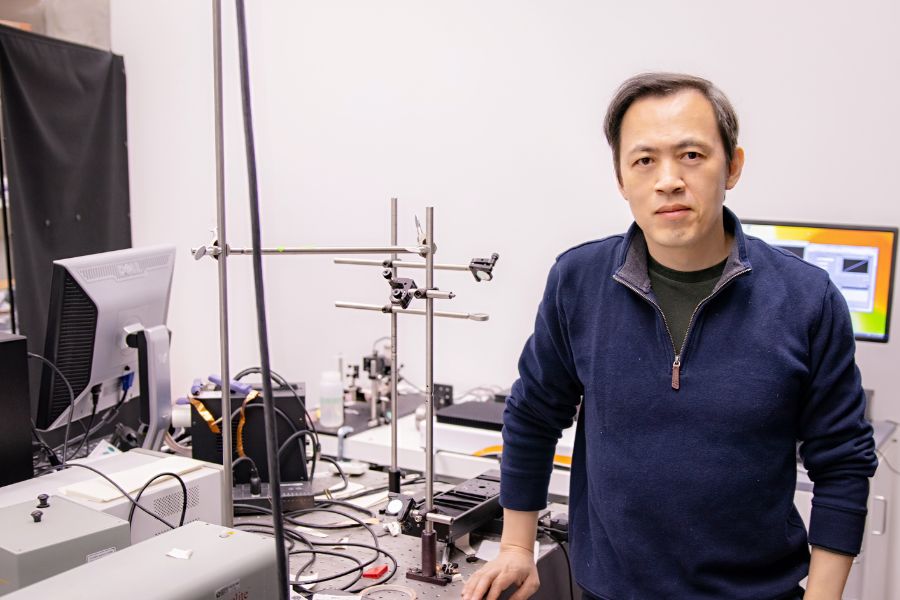

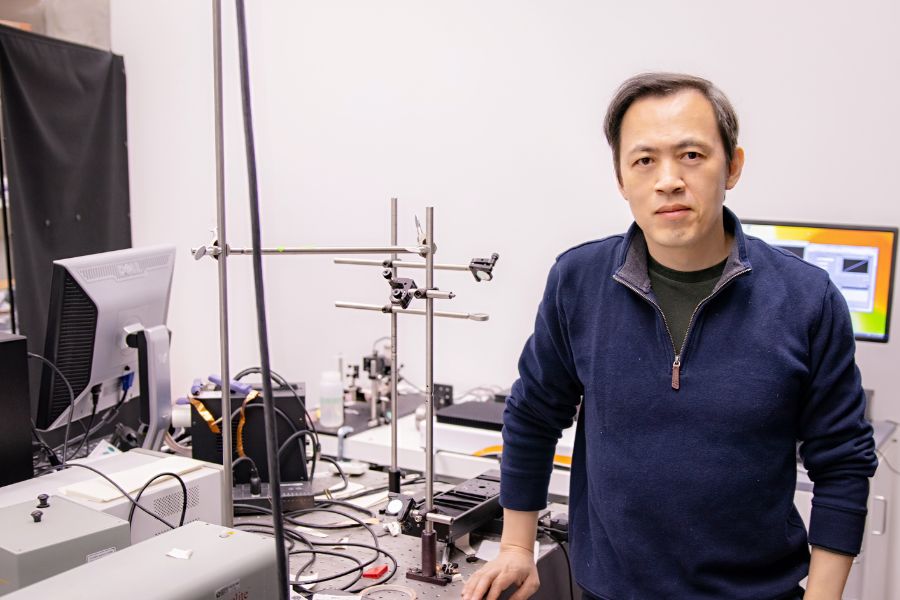

Gary Cheng Received 2025 ASME Blackall Machine Tool and Gage Award

Professor Gary Cheng and his team— have been selected the ASME Blackall Machine Tool and Gage Award for the paper titled "Nanoengineered Laser Shock Processing via Pulse Shaping for Nanostructuring in Metals: Multiscale simulations and experiments".

The Blackall Machine Tool and Gage Award is presented for the best current original paper, published by ASME during the two calendar years immediately preceding the year of the award, which clearly demonstrate the science and engineering technologies outlined in the paper, resulted in a significant contribution to the manufacturing processes and systems for the design or application of machine tools, gauges, dimensional measuring instruments, or new manufacturing technologies and metrology approaches.

Gary Cheng and co-authors — Drs. Sen Xiang, Xingtao Liu, Licong An, and Haozhang Qu are recognized for pioneering advancements in nano-engineered laser shock processing. Cheng’s development of dual-pulse laser shock peening (DP-LSP) leverages temporal pulse shaping to significantly improve metal strength and reliability by enabling precise thermal modulation during deformation. This innovation surpasses conventional single-pulse methods, achieving superior microstructural refinement and mechanical performance.

Cheng’s work integrates advanced experimentation with a multiscale computational framework, combining finite element modeling to predict temperature dynamics, phase-field modeling to elucidate nanoprecipitation mechanisms, and multiscale dislocation dynamics to analyze high-temperature dislocation interactions. This synergistic approach advances fundamental understanding while providing predictive tools for optimizing DP-LSP parameters.

By bridging theoretical models with practical applications, Cheng’s research establishes a systematic methodology for tailoring material properties through nano-engineered laser-based processing, driving advances in manufacturing science with direct industrial relevance. His work delivers notable improvements in metal performance, exemplifying scientific innovation and engineering impact.